Volcanic Eruption Necessitates UV Upgrade Project At The Largest Hatchery In Chile – A Case Study

Camanchaca Salmon Hatchery is located in Petrohué, in the southern part of Chile. Petrohué is the main town within the Vicente Pérez Rosales National Park. It is located on the western shore of Todos los Santos Lake, 80 Kilometers from the city of Puerto Varas, Los Lagos Region.

Project Background

The Hatchery’s UV upgrade project began in June 2015 in response to the eruption of the Calbuco volcano, which is considered by the Chilean National Service of Geology and Mining to be the third most dangerous volcano in the country. The volcano eruption released ashes and volcanic sand destroying UV equipment. The natural disaster made it necessary to repair many of the UV systems used to treat the water at the hatchery.

Camanchaca is the largest recirculation fish farm in Chile, producing millions of smolts per year. The facility began operating in 1965, catching and processing shrimp and langostino lobsters. In 1980, the facility diversified into other sea products, including aquaculture. In 2002, the hatchery began operating in a water recirculation mode for fish farming. The water treatment process used at the Hatchery includes mechanical and biological filters, oxygen injection and UV light for inactivation of any microorganisms in the water.

Camanchaca became the world’s first salmon producer to earn four stars for the Global Aquaculture Alliance’s (GAA) Best Aquaculture Practices (BAP) certification. This standard guarantees that salmon production is performed in a socially and environmentally responsible manner and is safe for human consumption.

While the facility was receiving awards and accolades for their aquaculture production, they were having challenges keeping their former UV system operating consistently and reliably. Spare parts were expensive and they often experienced periods of down-time, negatively affecting operations. The volcanic eruption caused permanent damage and accelerated the need to replace the UV system.

The Hatchery’s Operations Management insisted on an effective inactivation process; and therefore specified that the water treatment upgrade would include replacing the Ultraviolet (UV) units. They studied proposals from several UV Manufacturers; and according to their analysis, the Aquafine proposal was the most suitable and competitive. Aquafine was selected by Camanchaca due to its high safety standards, state of the art technology, and ease of installation and operation.

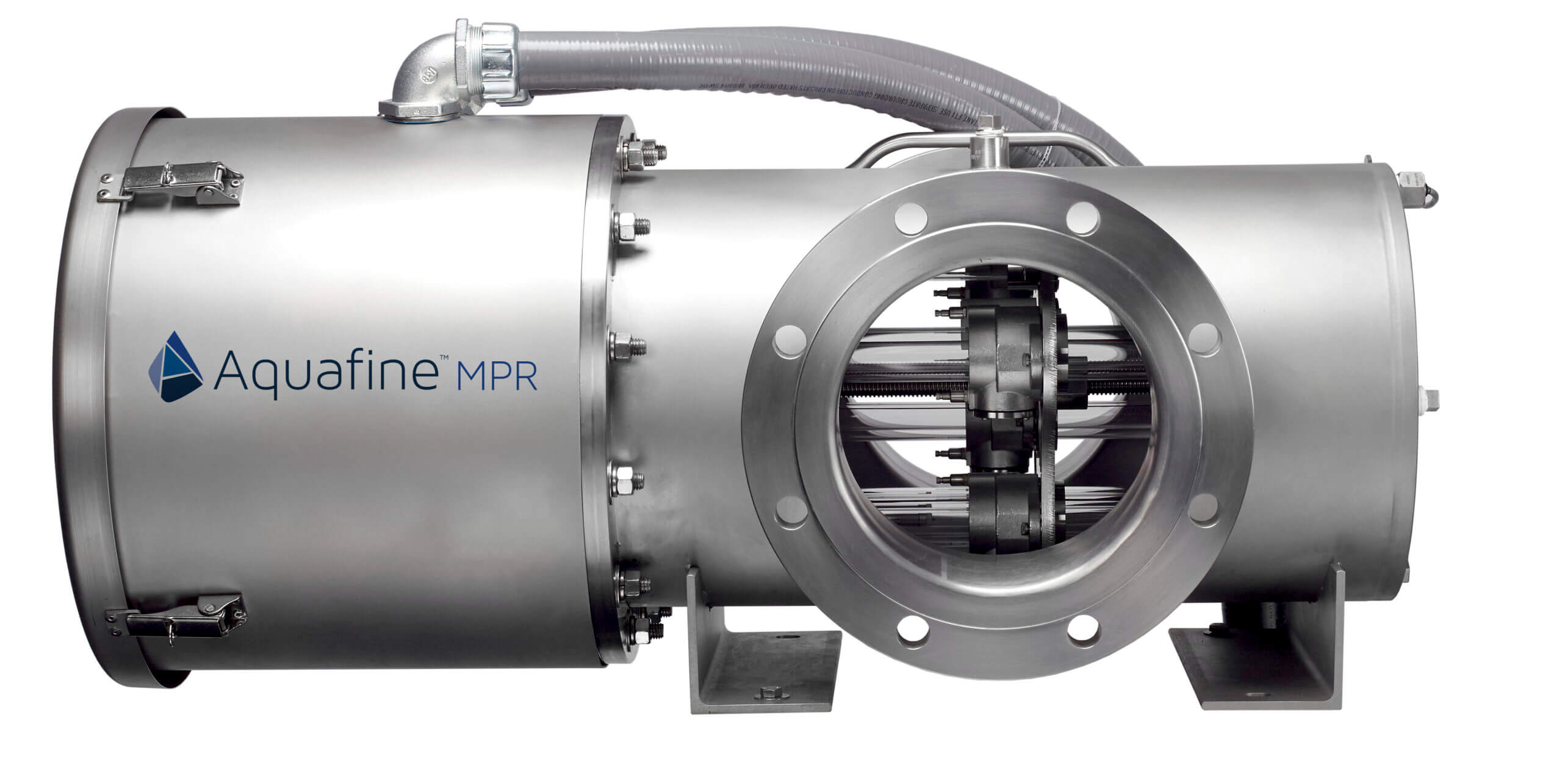

The Aquafine proposal consisted of 8 MPR2L12 models and 4 MPR4L12 models. One of the key benefits of the MPR UV system is the self-cleaning mechanism, which reduces maintenance and helps ensure the proper UV dose is delivered at all times. Without an automatic wiping system, the production line would need to be shut down periodically in order to remove and clean the quartz sleeves. The MPR series automates cleaning, reducing maintenance and maximizing uptime of the equipment.

“We have a long-term and highly trusting relationship, Aquafine has always responded promptly to all the requirements of the company. Aquafine is synonymous of good service and fair treatment” says Claudio García Huidobro, Operations Maintenance and Projects Manager of Camanchaca Hatchery.

Maintenance and uptime were key considerations in the selection of a new system. Aquafine’s maintenance costs and replacement parts were by far the most convenient. The compact configuration of the Aquafine MPR series, including the high powered UV lamps, enabled a flexible installation that helped to reduce construction costs. Finally, local technical service & support was critical for Camanchaca and helped them select Aquafine and the MPR as their UV solution.

The modernized facility, including 12 new Aquafine UV units, went into operation in early 2016 and has returned to full production meeting their sustainability and water quality goals.

The Aquafine Solution

Fish hatcheries and rearing facilities are constantly evaluating ways to improve the quality of their source water through various treatment methods including inactivation for infectious agents, temperature alteration, and recirculation with treatment for environmental and biologic contaminants. These measures promote healthy fish culture by optimizing the environment and minimizing diseases.

Fish hatcheries and rearing facilities are constantly evaluating ways to improve the quality of their source water through various treatment methods including inactivation for infectious agents, temperature alteration, and recirculation with treatment for environmental and biologic contaminants. These measures promote healthy fish culture by optimizing the environment and minimizing diseases.

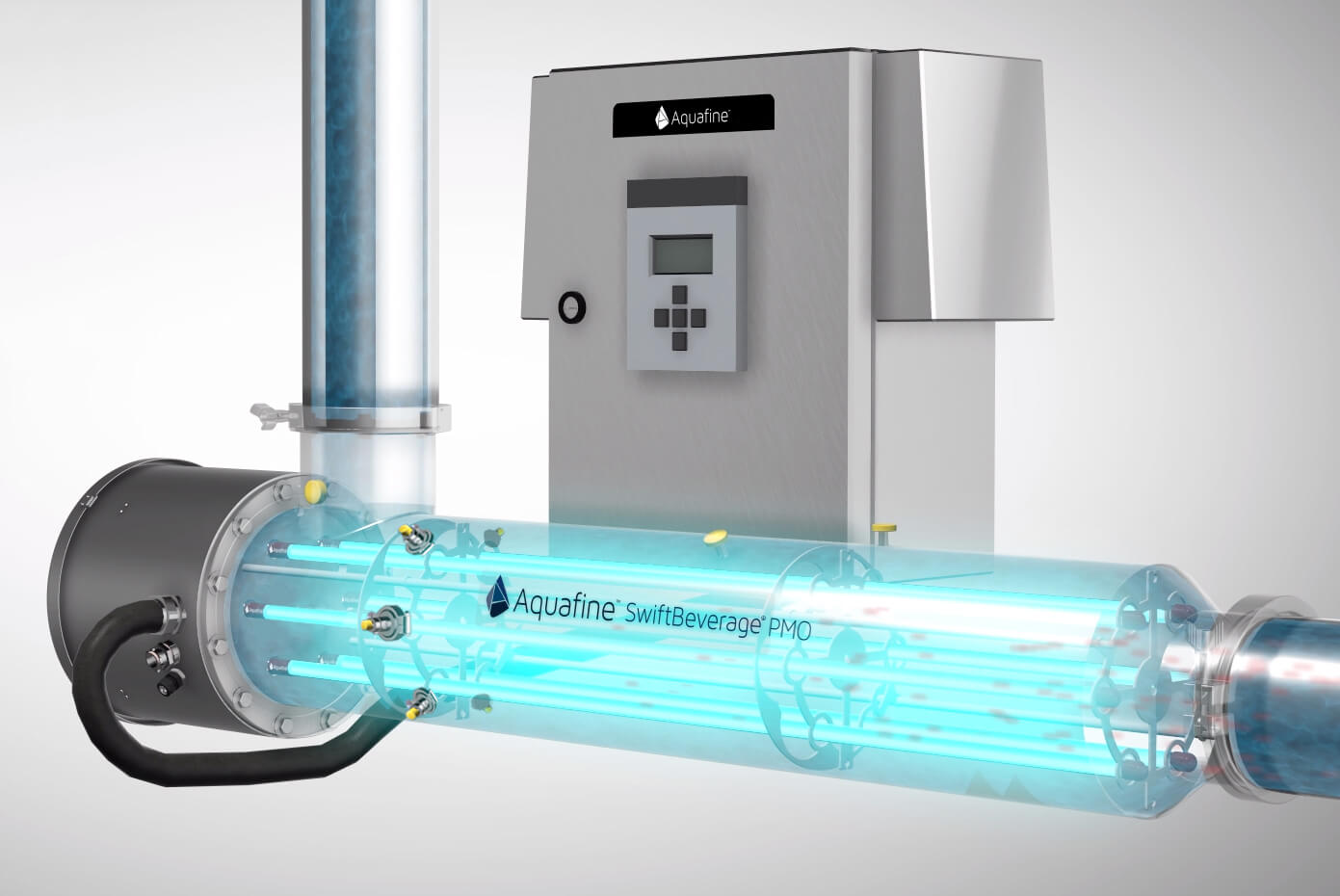

UV light inactivation systems play an important role in a complete water treatment process in aquaculture facilities. System designs are available in both closed pipe and open channel arrangements to provide the greatest flexibility to the hatchery. UV system components, including lamps, lamp drivers, sensors and cleaning systems have been thoroughly tested and validated – ensuring reliable performance and simple maintenance – key to water treatment processes for Aquaculture.

System Design Parameters

• Average flow capacity: 350 m³/hr per unit

• Peak flow capacity: 400 m³/hr per unit

• Ultraviolet transmittance (UVT): 90% at 254 nm

• Treatment requirement: 70 mJ/cm²

• UV Solution: 12 total Units; 8 MPR 2L12 and 4 MPR 4L12 models

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...