Wastewater Treatment Plant In Arkansas Says Goodbye To Chlorine & Hello To UV

When it comes to wastewater treatment, two common methods are widely used today: chemical and physical. Chemical inactivation is typically achieved by chlorine gas or hypochlorite, whereas physical inactivation is by UV light. An increased awareness of the disadvantages of chemical treatments, specifically chlorine, continues to prompt wastewater treatment plants to convert to UV.

Take the City of Hot Springs, Arkansas for example. Officials there decided to convert the treatment at its regional wastewater treatment plant from chlorine to UV. This was done in an effort to eliminate the safety issues associated with chlorine and to also protect and improve receiving waters.

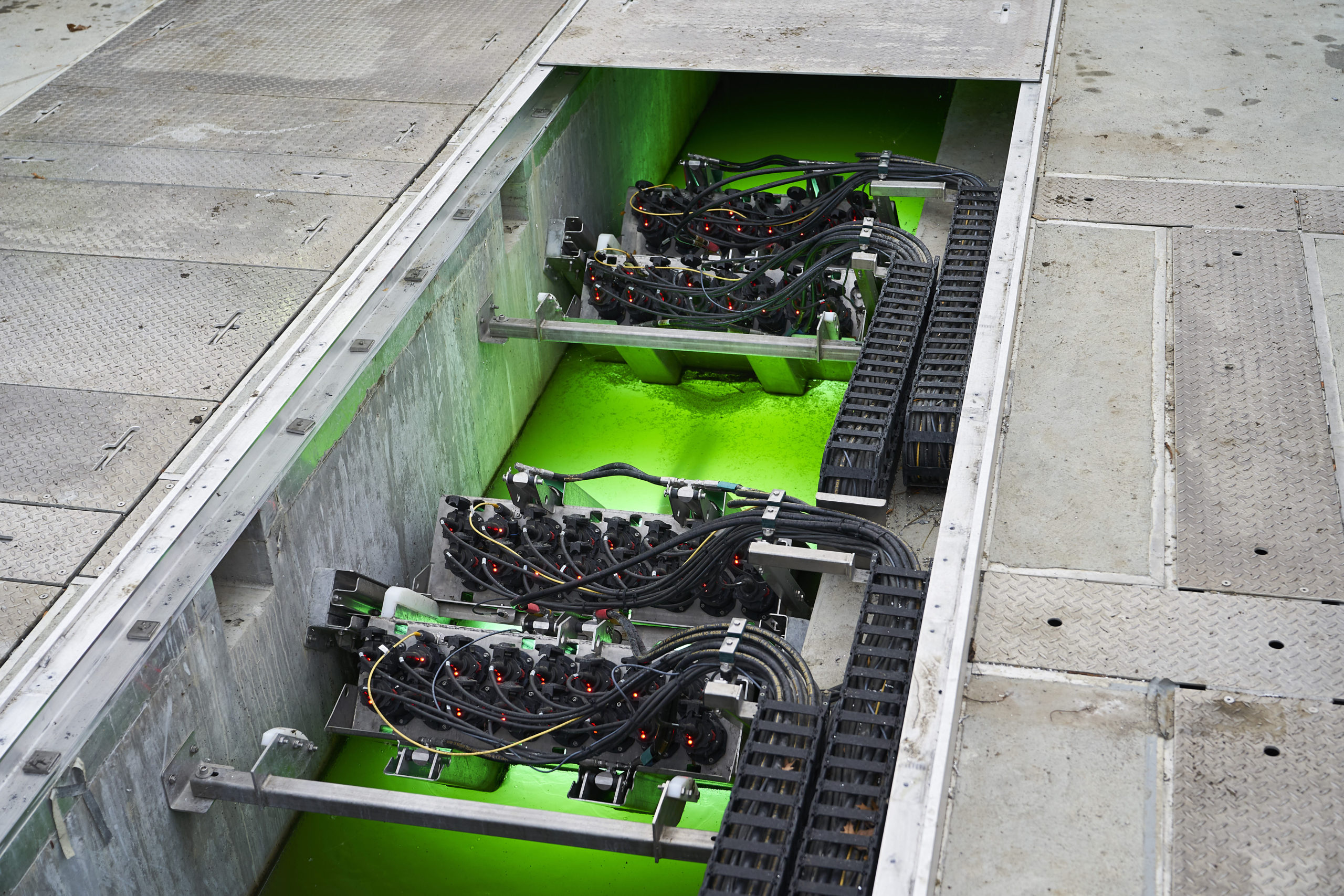

The UV system that the city selected was our TrojanUVSigna®. The TrojanUVSigna is designed to fit into existing chlorine contact chambers without major modifications to the channel depth or width. It also incorporates innovations, including TrojanUV Solo Lamp® Technology, to reduce the total cost of ownership and drastically simplify operation and maintenance.

UV is Effective

With chemical inactivation, the effluent is exposed to chlorine gas (or liquid chlorine) in large tanks to ensure sufficient contact time to inactivate microorganisms. However, in some jurisdictions regulations place stringent limits on chlorine levels in the final effluent to minimize by-products being discharged into receiving water. In those cases, an additional chemical process called dechlorination is required to remove residual chlorine, ultimately adding more complexity and cost to the process.

Alternatively, UV provides an efficient and effective way to inactivate wastewater. It has significant benefits compared to chlorine and has been proven effective in thousands of installations globally. Furthermore, UV is not affected by temperature or pH of the effluent and does not create by-products.

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...