Improving Water Quality At Fish Hatcheries With UV – A Case Study

Located on the Klamath River in Hornbrook, California, Iron Gate Hatchery is a salmon and steelhead hatchery that releases fish back to the Klamath River. Due to the presence of the fungus Saprolegnia sp and microorganisms (Flavobacterium psychrophila and Metallogenium sp), hatchery yield is thwarted due to disease. Poor water quality supports an environment favoring these fish microbes and as a result, hatchery managers must produce 10,000,000 eggs to release 6,000,000 fish annually.

About Iron Gate Hatchery

Approximately 6,000,000 Chinook, 75,000 Coho, and 200,000 Steelhead are produced annually. The spawning and trapping facility was initially constructed in 1962, with the addition of eight 400-ft. raceways, and a hatchery building in 1966. Over successive years, an auxiliary fish ladder, three small recirculating round tanks, and two settling ponds for waste treatment have been added. Located on the south side of the Klamath River in Siskiyou County, eight miles northeast of Hornbrook, CA, Iron Gate Hatchery operates with a gravity fed, flow through system and the water allotment is 50 CFS daily. The hatchery is currently owned by PacifiCorp of Portland, Oregon and operated by the California Department of Fish and Wildlife.

The hatchery obtains its water supply from Iron Gate Reservoir. Water is gravity fed from the dam via a 30-inch penstock, reducing to 24 inches before passing through an aeration tower. No treatment of influent water is performed except for aeration through the tower.

UV as a Solution to Water Quality Issues

Three hatcheries were identified and approved for emergency California State funding for remedies to curtail loss of eggs and fish in the hatchery building. Among those was the Iron Gate Hatchery along with the Merced and Nimbus hatcheries. Discharge from the facility returns to the Klamath River after settling ponds. Best management practices virtually eliminate the use of chemicals as an option for treatment. A meeting to discuss the hatchery water quality was arranged by the Quality Water Systems of Medford, Oregon, who had performed pilot studies at Iron Gate Hatchery, and Aquafine distributor, Calhoun & DeJong, was contacted to lend support.

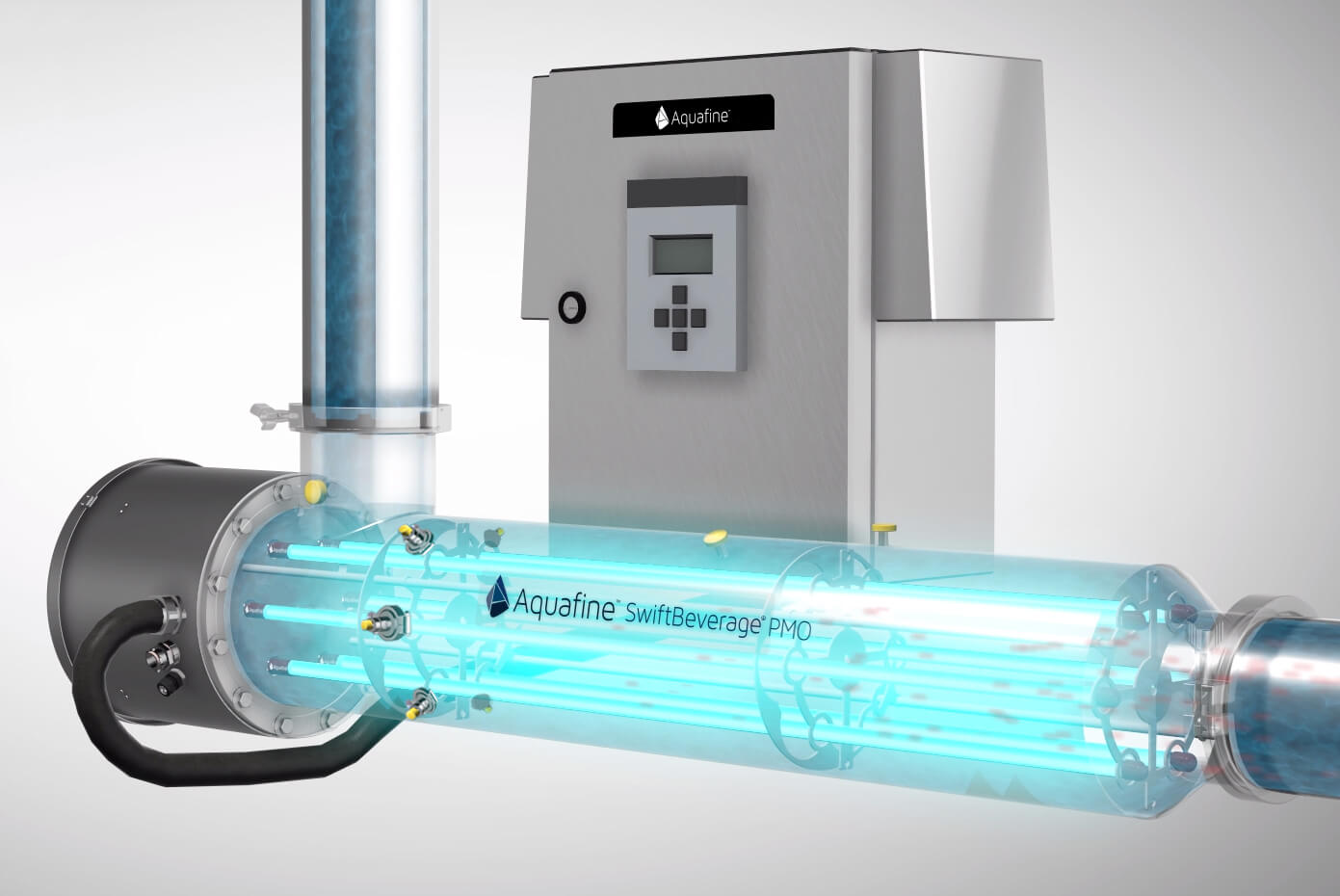

The Aquafine UV System Solution

After careful evaluation of technologies, the investigators were confident that UV was the right solution. In early May 2015, Aquafine was presented as a potential UV provider for the Iron Gate Hatchery. Aquafine UV System and Calhoun & DeJong met with the Quality Water Systems Department at the Iron Gate Hatchery, along with several officials from the California Department of Fish and Wildlife. After initial ultraviolet transmittance (UVT) testing of several samples and further on-site testing was completed, there was still concern regarding effective dosage requirements to thoroughly inactivate for the three identified microbes. After further deliberation on the UV dose to be applied, Aquafine UV System was chosen as the lead expert for the Iron Gate Hatchery project.

TrojanUVLogic systems were installed and commissioned at the Iron Gate Hatchery in October 2015, joining in the States’ effort to save commercially valuable fall Chinook salmon by treating the water and reducing the possibility of disease outbreaks.

Iron Gate Hatchery’s Aquafine UV system features two parallel, horizontally mounted 316L stainless steel 18 AL 40 treatment chambers, and a UL TYPE-3R 304 stainless steel control cabinet featuring a microprocessor-based controller. The units have been installed outside the hatchery building downstream of the filtration system. The filtration system and UV components are appropriate to treat 1.5 CFS, which meets the hatchery’s requirements for operating 104 vertical incubation stacks.

The filtration system and Aquafine’s UV solution have sufficiently cleaned the water to make salmonid egg incubation more predicable at the hatchery. Increased egg and fry survival was very evident as being a direct result of the water treatment in the hatchery building. Prior to the installation of the Aquafine TrojanUVLogicTM 18AL40’s, it took some 10,000,000 eggs to produce 6,000,000 healthy fish, or a 60% yield from eggs to fish. However, after UV installation, yield has improved to 75%-80%. Additional labor was saved at the end of the incubation period in cleaning and preparing the hatchery building for the upcoming year.

UV Systems Play an Important Role in Aquaculture Facilities

Fish hatcheries and rearing facilities are constantly evaluating ways to improve the quality of their source water through various treatment methods including inactivation for infectious agents, temperature alteration, and recirculation with treatment for environmental and biologic contaminants. These measures promote healthy fish culture by optimizing the environment and minimizing diseases.

UV systems play an important role in a complete water treatment process in aquaculture facilities. System designs are available in both closed pipe and open channel arrangements to provide the greatest flexibility to the hatchery, and components have evolved rapidly over time to provide some of the most reliably performing and easy-to-operate technology in water treatment applications.

System Design Parameters:

• Flow capacity (GPM): 675 GPM

• Ultraviolet transmittance (UVT% @nm): 95% @ 254 nm

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...