Loosening The GRIP Of Southern California’s Reliance On Imported Water

Throughout recent years of drought conditions, the Water Replenishment District of Southern California (WRD) has been working to preserve the quality and quantity of groundwater in the subsurface aquifers that underlie their service area in southern Los Angeles County.The WRD was formed in 1959 to protect and replenish groundwater resources and has been buying billions of gallons of imported water from Northern California and the Colorado River to help replenish the basin, which is expensive and prone to disruption. However, the WRD has found a more cost-effective solution that will allow the region to be self-reliant in terms of its groundwater replenishment needs.

GRIP – an Advanced Water Treatment Facility

Enter the Groundwater Reliability Improvement Project, or GRIP, a 10 million gallon per day (MGD) advanced water treatment facility that will fully purify recycled water that is currently being sent to the ocean and will return it to the groundwater basin. The GRIP facility has been strategically positioned next to the San Gabriel River in the city of Pico Rivera, allowing it direct access to a recycled water pipeline that leads to the spreading grounds. Once the water is spread, it will percolate and naturally filter through layers of sand and gravel before reaching the deeper drinking water aquifers.

GRIP is the cornerstone project of WRD’s 13-year long Water Independence Now (WIN) effort to end the region’s dependence on outside water sources.

Details About the GRIP Facility

The GRIP facility itself promises to be extraordinary. Slated for completion by fall of 2018, the site will include the advanced treatment facility as well as a 20,000 square-foot community learning center. The learning center will include an educational exhibit area to provide visitors an overview of the water treatment processes, as well as community meeting rooms for public use.

Together, with an impressive outdoor amphitheater, the landscaping around the building will feature drought-tolerant gardens and give visitors a first-hand look at how GRIP will benefit the region as a whole.

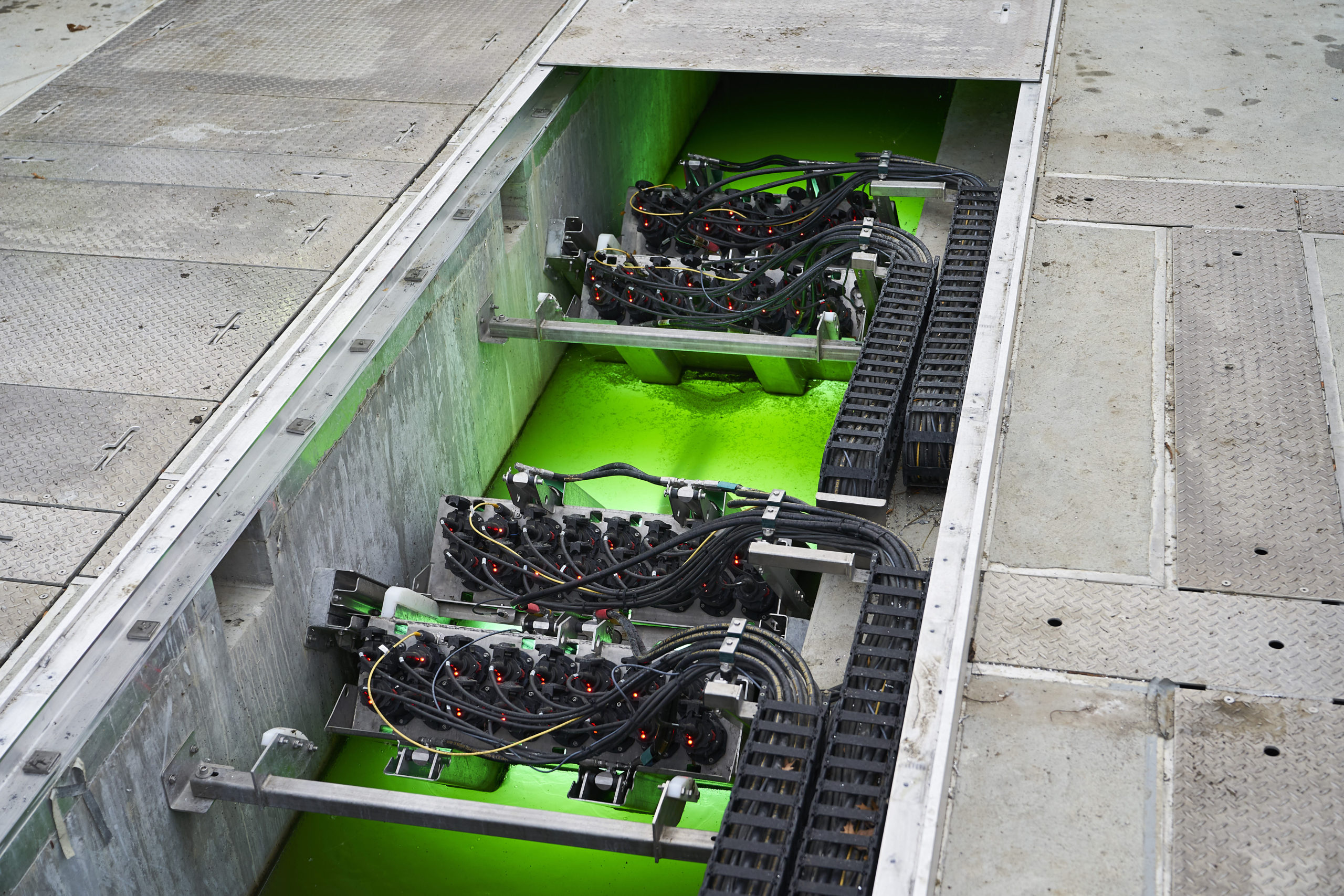

To help the WRD with its water sustainability initiative, Trojan was chosen to supply one of our most reliable and celebrated advanced oxidation systems – the TrojanUVPhox® – for installation at the GRIP facility. The TrojanUVPhox uses high-output amalgam UV lamps in a pressurized chamber to perform UV-photolysis and UV-oxidation treatment.

The TrojanUVPhox uses the UV advanced oxidation process (UV AOP) to reduce a range of contaminants, even difficult-to-treat 1,4-dioxane and NDMA.

Designed to maximize electrical efficiency, the unique design allows for multiple chambers to be installed in a compact footprint. The TrojanUVPhox, one of the final treatment steps in the Plant, will act as a barrier to any chemical contaminants that pass through upstream membranes while simultaneously providing high-level inactivation of microorganisms.

Moving Into the 21st Century

As we move further into the 21st century and resources continue to be strained under humanity’s growing pressures, we must inspire the next generation of young minds to address the water challenges of tomorrow.

To that end, Trojan is currently working with WRD to provide educational materials and exhibits at GRIP that will educate visitors of all ages regarding the UV advanced oxidation process and the importance of water treatment and beneficial reuse.

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...