Achieving High-Purity Water for Microelectronics: Sustainable Solutions with Aquafine Technology

As we rapidly progress towards a more technologically dependent world backed by AI advancements, progressive medical devices, and automation, the demand for microelectronics has been increasing rapidly too. The unique nature of microelectronics fabrication processes necessitates a careful approach to water treatment.

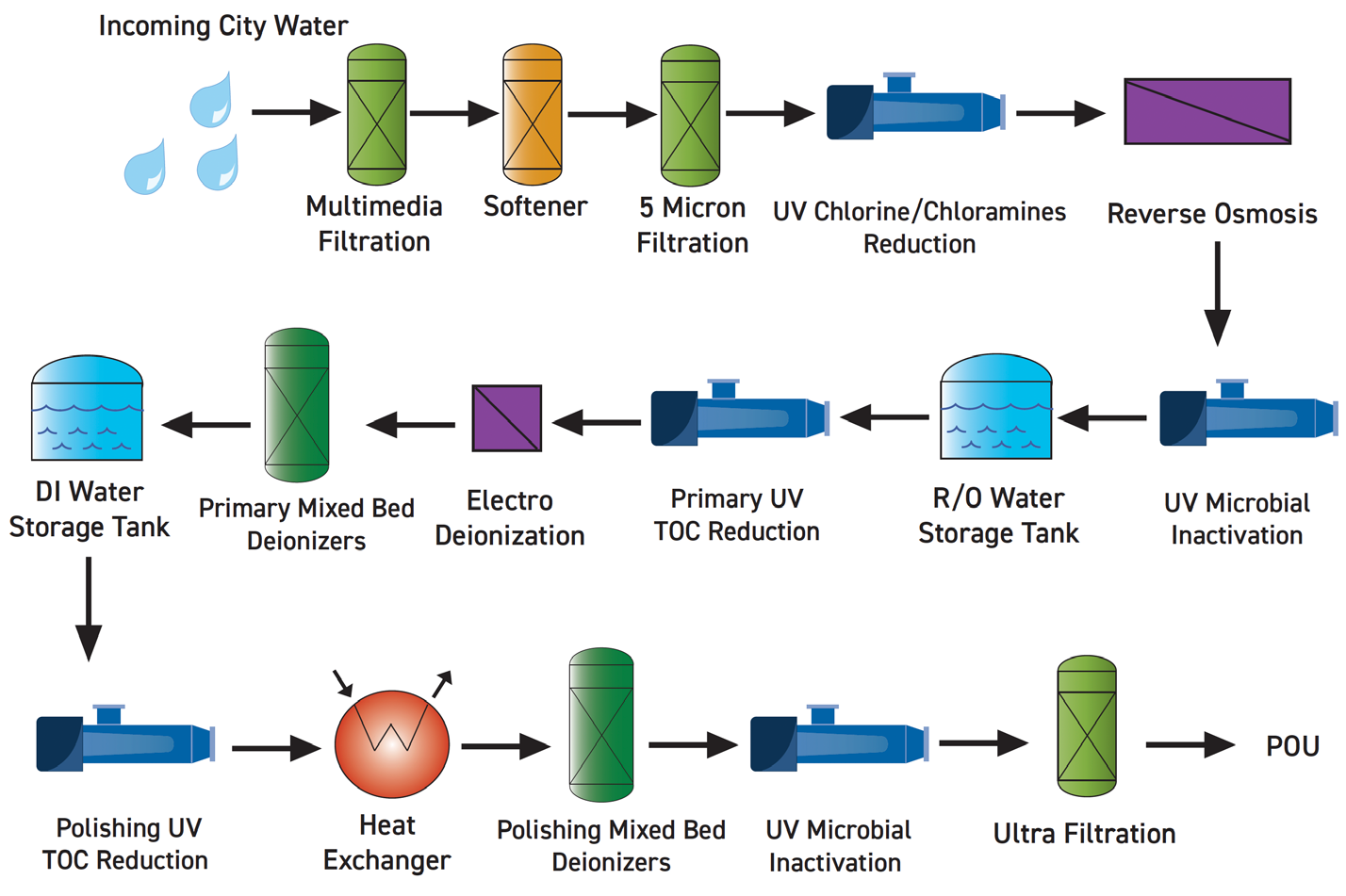

Not only does the fabrication of microelectronics utilize a wide array of chemicals that pose a challenge to treat wastewater effectively, but it also demands an unparalleled level of water purity, with total organic carbon (TOC) levels often needing to be less than one part per billion. With the industry being challenged to balance effective treatment with costs, UV advanced oxidation processes (UV AOP) have emerged as an ideal solution. UV AOP extends beyond traditional UV treatment of microbiological contaminants by incorporating the use of oxidants, such as hydrogen peroxide, to target and destroy trace organic contaminants effectively. This enhances the overall efficiency of the water treatment system.

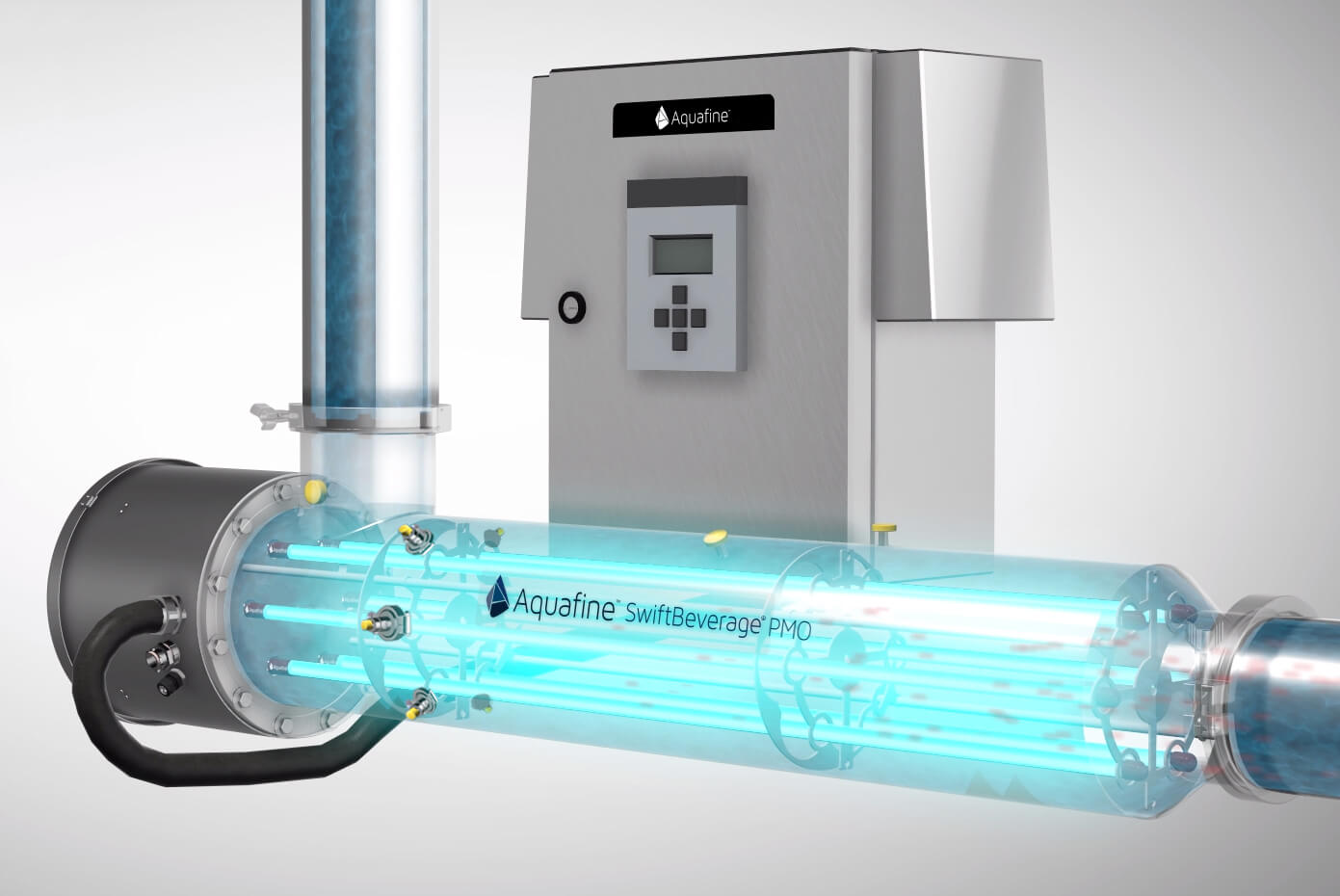

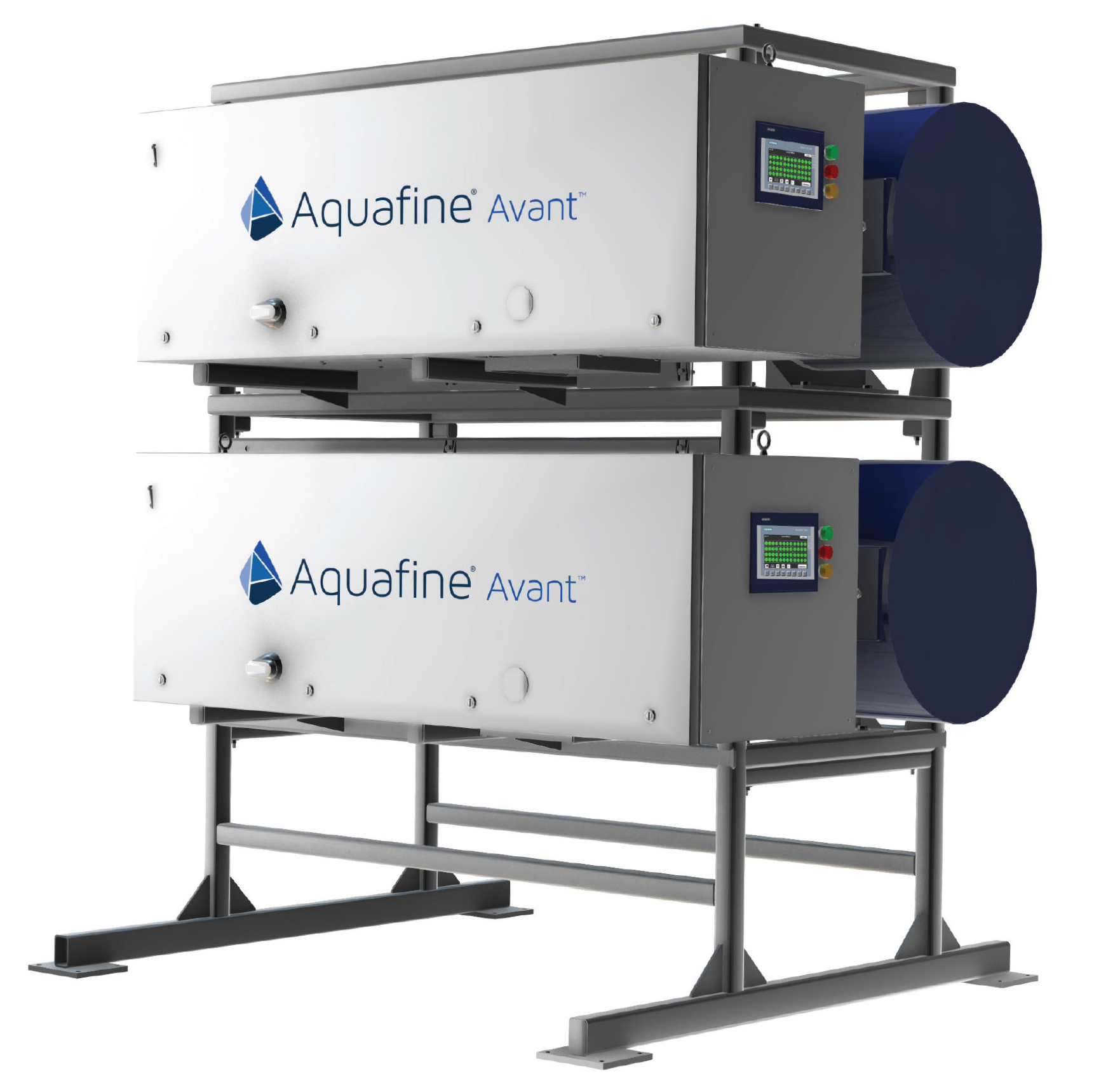

Aquafine technology boasts a long history in microelectronics, with systems still operational since 1980. Newer Aquafine models, such as the Avant product line, showcase advancements in energy efficiency. Through the optimization of lamp

technology and computational fluid dynamics (CFD) modeling, these systems achieve the same flow rates with reduced lamp requirements. This results in significant energy savings and operational efficiency. Additionally, the Avant series features a unique function allowing for the dimming and regrouping of lamps, offering flexibility to adapt to changing water conditions and chemical inputs. This capability ensures optimal performance and power usage tailored to specific microelectronics facility requirements.

In the ever-evolving landscape of microelectronics, the demand for cutting-edge technology intertwines with the need for sustainable practices. As microelectronic manufacturers pivot toward localized production, Aquafine offers historical expertise combined with innovative solutions.

To learn more about the Avant product line and “How Microelectronics Fabricators Are achieving Net-Zero Discharge” please use the links below:

Aquafine Avant Series

How Microelectronics Fabricators Are Achieving Net-Zero Discharge

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...