Aquaculture Water Treatment: Why Use UV?

The aquaculture industry relies on the quality of water used to incubate fish eggs and rear juvenile fish. Water abundance and purity continue to decrease, while disease concerns found in source waters continues to increase. Aquaculture water treatment has remained a valuable tool in addressing these concerns.

This phenomenon is due in part to the increased demand for water from growing urban areas, continued pollution of our natural waters and the introduction of new, microorganisms to natural waters through a variety of routes: bird, animal and human activities, including ballast water discharge. This brings many challenges to a rapidly growing industry.

How do I Mitigate These problems?

There are solutions available today which can help to overcome them. Increasingly, fish hatcheries and rearing facilities are evaluating ways to improve the quality of their source water, while off-setting quantity losses through the implementation of recirculating water systems.

This is leading more fish hatcheries to install sophisticated water treatment systems.

Systems designed to:

- Enhance overall water quality

- Reduce the possibility of disease outbreaks

- Balance water needs due to the lack of available water from natural sources.

Ultraviolet (UV) light treatment systems play an important role in a complete water treatment process in aquaculture facilities. System designs are available in both closed vessel and open channel arrangements to provide the greatest flexibility to the hatchery, and components have evolved over time to provide some of the most reliably performing and easy-to-operate technology in aquaculture water treatment applications.

Technician inspects an open channel water system.

Inactivation

UV systems significantly reduce microorganism counts in incubation and rearing facilities and have proven to be the most cost effective treatment technology for the inactivation of various types of microbes harmful to many species of fish.

Residual Ozone Reduction

Ozone is often used in a fish hatchery to enhance the quality of problematic water sources used for incubating and rearing fish. However, residual ozone in the water can be extremely toxic or fatal to the aquatic life being reared. To ensure that the fish are not exposed to residual ozone, there are often one of two removal processes employed. The first is an ozone off-gassing column which vents ozone to atmosphere; this may not be the best design based on its toxic effect to the environment. The second method is applying 254nm UV energy to consume the residual ozone in the bulk water prior to contacting the fish.

How can Aquafine UV Systems help?

We’ve helped more than 200 organizations with differing needs across multiple industries, including:

- Hatcheries

- Incubation, Rehabilitation Facilities

- Depuration Facilities

- Aquariums

- Zoos

- Processing Plants

- Influent/Effluent Treatment

With Aquaculture UV system designs unparalleled in performance, lifetime performance guarantee, and worldwide service and distribution network, we are committed to providing superior quality product and the latest advancements in treatment technology that is hassle free.

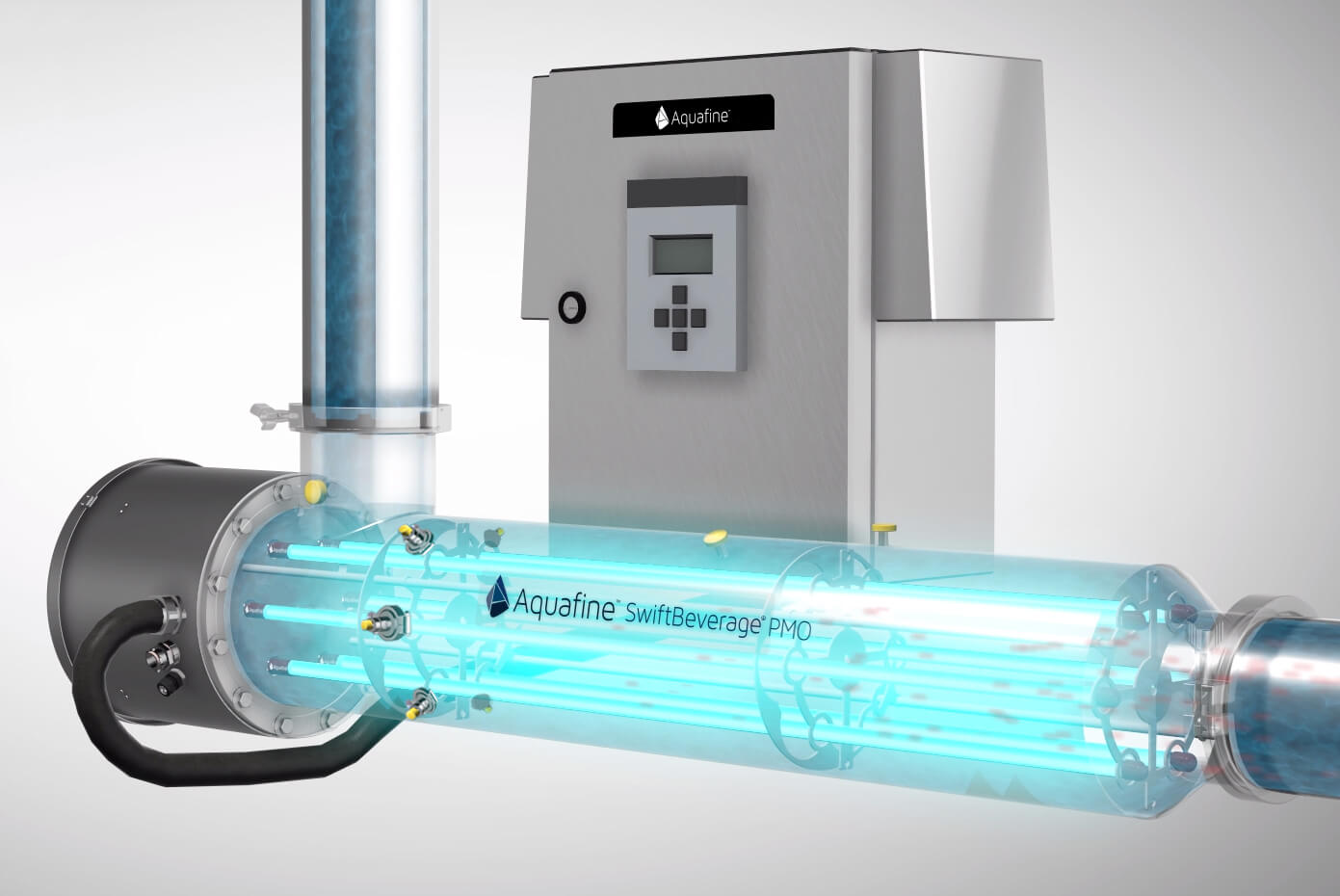

An example of a closed vessel system.

If you’re interested in learning more, reach out today or visit our website and read further about aquaculture water treatment.

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...