Why Dairy Producers Are Considering The Switch To UV Treatment

Recent advancements are making it more appealing than ever for the dairy industry to replace heat pasteurization in favor of ultraviolet inactivation to treat water for its production needs.

Complying With the Pasteurized Milk Ordinance (PMO)

To comply with the Pasteurized Milk Ordinance (PMO) in producing Grade-A milk for interstate shipment, dairy plants are required to pasteurize water that comes in contact with the same surfaces as the milk. Since 2011, UV inactivation has been approved to replace thermal pasteurization for this water, if certain criteria are met.

Aquafine has energy-efficient treatment solutions for this application. That’s good news for dairy producers that expend significant resources to generate high-quality water for various processes within their operations. Commercial UV products for the dairy industry can be applied with confidence because the PMO has set stringent standards for UV treatment, far exceeding those required for drinking water.

Treating Water With UV

Treating water is at the core of the PMO, which includes the following requirements of UV products:

- 100 percent of the water is treated. The equipment must initiate flow diversion if there is insufficient UV energy for treatment, or if the system operation is otherwise compromised;

- UV dose of 186,000 μW-s/cm2 or a 4-log adenovirus equivalent

- Designed for frequent cleaning;

- One germicidal UV intensity sensor per lamp;

- Recording of flow, water quality (UV transmittance), UV dose; and

- Made of non-toxic materials.

Aquafine SBV1200-PMO units treating water used in butter production facilities in California.

The UV Technology Advantage

The traditional heat pasteurization process relies on a heat exchanger, and a significant amount of energy, to enable the process water to reach a high temperature over a long time.

By comparison, UV systems expose the process water to ultraviolet light over a matter of seconds to achieve inactivation. UV is a physical process, meaning that the treated water quality (e.g., pH, color) is unchanged.

It takes far less energy with UV than heat pasteurization. For example, inactivating 480 gpm can be accomplished with a typical 3.1 kW UV system. Heat pasteurization of the same water requires approximately 400 kW, even using conventional heat recovery. This is more than 100 times the energy compared to UV!

In addition to a dramatic reduction in energy usage, switching from heat pasteurization to UV inactivation eliminates the need for heat exchangers and their associated maintenance such as leak repair, seal replacement, and scale removal.

The bottom line is that switching from heat pasteurization to UV inactivation has now become economically attractive.

Additionally, UV systems can enable space savings as they have lower footprint in comparison to pasteurization units used.

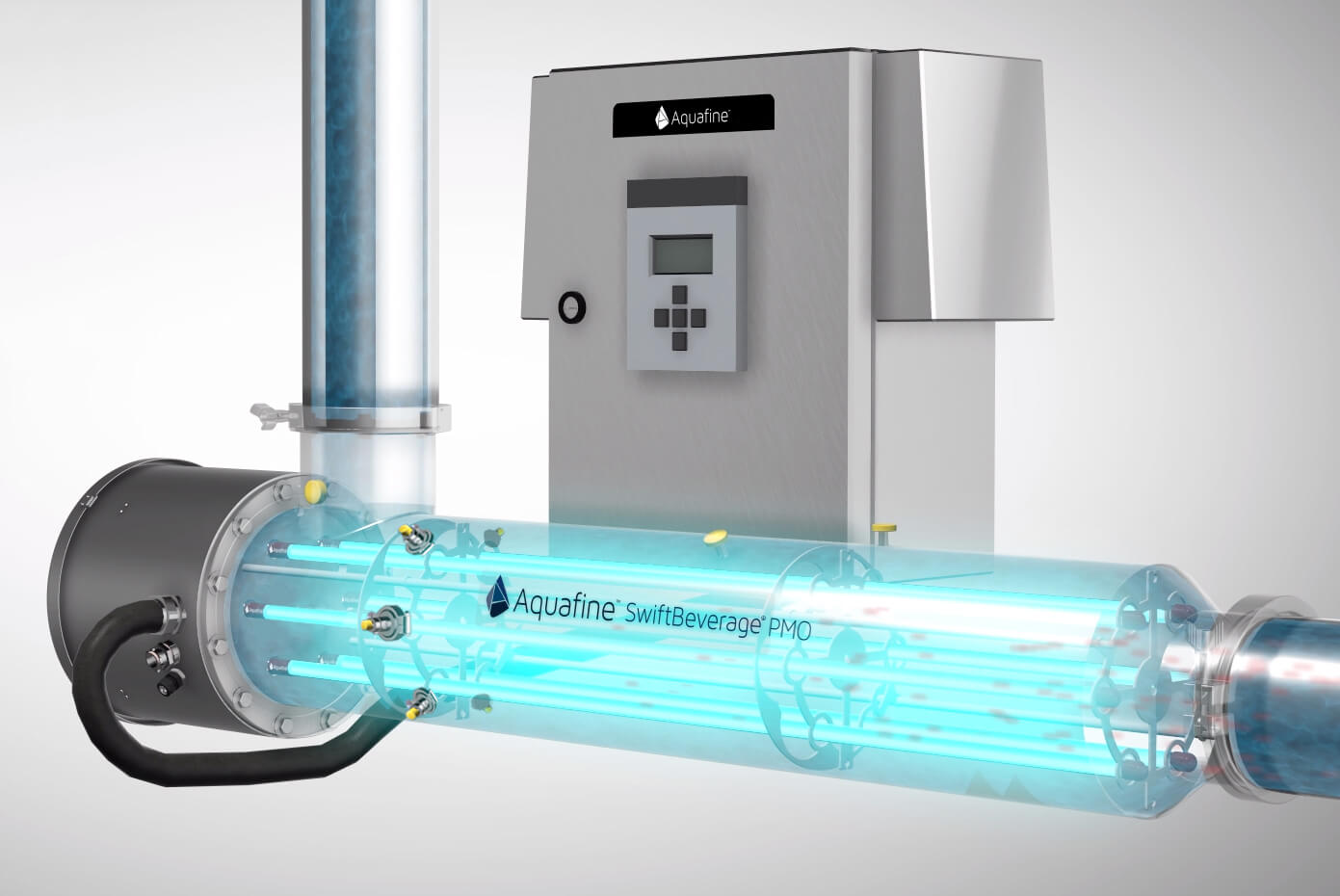

The Aquafine SwiftBeverage UV System

An example of a technology that is fully compliant with the current regulations is the Aquafine SwiftBeverage UV System.

This product line has been installed across the country in states such as California, New York and Wisconsin in dairy production/processing plants. The systems are validated for performance by independent, third-party engineering firms using the same protocols required by the EPA for drinking water facilities.

The Aquafine SwiftBeverage PMO fully complies with PMO for the dairy industry.

Given the potential for substantial energy savings and the reduction in maintenance with heat exchangers and the associated ancillary equipment, dairy producers now have incentive to consider UV systems to provide treated water for their dairy needs.

Reach out today! We’d be happy to provide more information, or set up time to discuss solutions for your dairy application.

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...