Getting The Most Out Of A Residential UV Water Treatment System

A UV water treatment system provides a low-maintenance option for physical treatment of private water sources, including dug or drilled wells, surface water like lakes, and for harvested rainwater. While each of those sources presents unique water quality challenges which can impact the effectiveness of the UV system, the fundamental premise is the same. For UV to be completely effective, the UVC light generated by the lamp needs to be able to pass through the water unimpeded so that it can inactivate any microorganisms present.

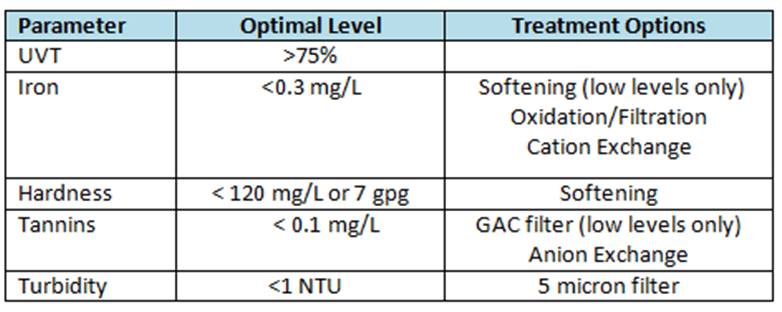

The ability of the water to transmit UVC rays is known as ultraviolet transmittance (UVT). Generally, for effective treatment, the UVT of the source water needs to be greater than 75%. The tricky part is that UVT does not directly correlate with the visual clarity of the water. Take, for instance, a glass of distilled water and add to it a teaspoon of sugar. Once the sugar is fully dissolved, the water will look just as clear as before. But the UVT will have dropped from 100% to as little as 5%. Many water contaminants will have a similar impact.

The ability of the water to transmit UVC rays is known as ultraviolet transmittance (UVT). Generally, for effective treatment, the UVT of the source water needs to be greater than 75%. The tricky part is that UVT does not directly correlate with the visual clarity of the water. Take, for instance, a glass of distilled water and add to it a teaspoon of sugar. Once the sugar is fully dissolved, the water will look just as clear as before. But the UVT will have dropped from 100% to as little as 5%. Many water contaminants will have a similar impact.

The presence of tannins in the source water, for instance, can easily cause UVT to drop to between 75% and 50%. Tannins are commonly found in surface waters such lakes, rivers, and rainwater, and consist of natural organic matter that is picked up as water passes through peaty soil or decaying vegetation. You’ll likely know if tannins are present as they can give water a slight yellow tinge, tart taste, and/or earthy odour. The problem is that tannins absorb UVC light as it shines through the water. As a result, the dose of UVC light reaching the microbes is reduced and inactivation is incomplete. While it’s possible to remove small amounts of tannins with a granular activated carbon (GAC) filter, keep in mind that these have a limited absorption capacity and will need to be changed regularly. On the other hand, an anion exchange unit in which the absorption media is repeatedly and automatically regenerated (much like a water softener) will handle tannin removal more effectively.

Common groundwater contaminants include hardness minerals (Ca2+, Mg2+) and iron. Like tannins, iron can absorb UVC light, preventing complete treatment. However, all three minerals are troublesome in that they can, over time, deposit on or foul the quartz sleeve. This is accelerated by heat from the lamp and produces a white coating or buildup, much like will happen on glassware and pipes when hard water is used in the home. Again, this build-up results in decreased UV dose and incomplete treatment. Hardness and low levels of iron (<2 mg/L) are typically removed by cation exchange (water softener). At higher iron levels, removal can be achieved using oxidation and filtration. Or better yet, the dissolved iron can also be removed, along with calcium hardness, by using synthetic zeolite-based cation exchange media.

Turbidity is another interfering contaminant that can be present in either ground or surface water. It is measured in nephelometric turbidity units (NTU). At levels above 1 NTU, suspended matter can cause two issues with the UV inactivation process. First, scattering of UV light reduces the effectiveness of the treatment. The second issue, shadowing, is a phenomenon whereby microbes can be embedded in suspended particles and literally be shielded from the UV light as they pass through the chamber. Turbidity is easily managed with good filtration practices, though. To ensure a high level of microbial inactivation, always use a 5-micron filter before the UV system.

Turbidity is another interfering contaminant that can be present in either ground or surface water. It is measured in nephelometric turbidity units (NTU). At levels above 1 NTU, suspended matter can cause two issues with the UV inactivation process. First, scattering of UV light reduces the effectiveness of the treatment. The second issue, shadowing, is a phenomenon whereby microbes can be embedded in suspended particles and literally be shielded from the UV light as they pass through the chamber. Turbidity is easily managed with good filtration practices, though. To ensure a high level of microbial inactivation, always use a 5-micron filter before the UV system.

Pre-treatment is a critical part of effective treatment with ultraviolet light. Manufacturer specifications and water testing results should always dictate your approach to designing the full water treatment system, however, some guidelines follow:

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...