Illinois’ First Environmental Contaminant Treatment System

The Otter Lake Water Commission has installed our TrojanUVSwift®ECT – a technology which optimizes the treatment of environmental contaminants, particularly taste and odor-causing compounds found in surface waters. This is the first ECT installation and the first UV system to receive inactivation credits in the State of Illinois.

Built in 1969, the Otter Lake Water Commission treatment plant serves approximately 17,000 people in the towns of Auburn, Divernon, Girard, Pawnee, Thayer and Virden. The treatment plant has a maximum flow rate of 1.5 million gallons per day.

In 2006, concentrations of MIB, a contaminant responsible for taste and odor (T&O), exceeded 6,000 ng/L in water treated by the Otter Lake Water Commission. In 2010, an LT2 Bin classification of 2 was issued, requiring an additional 1-log Cryptosporidium inactivation.

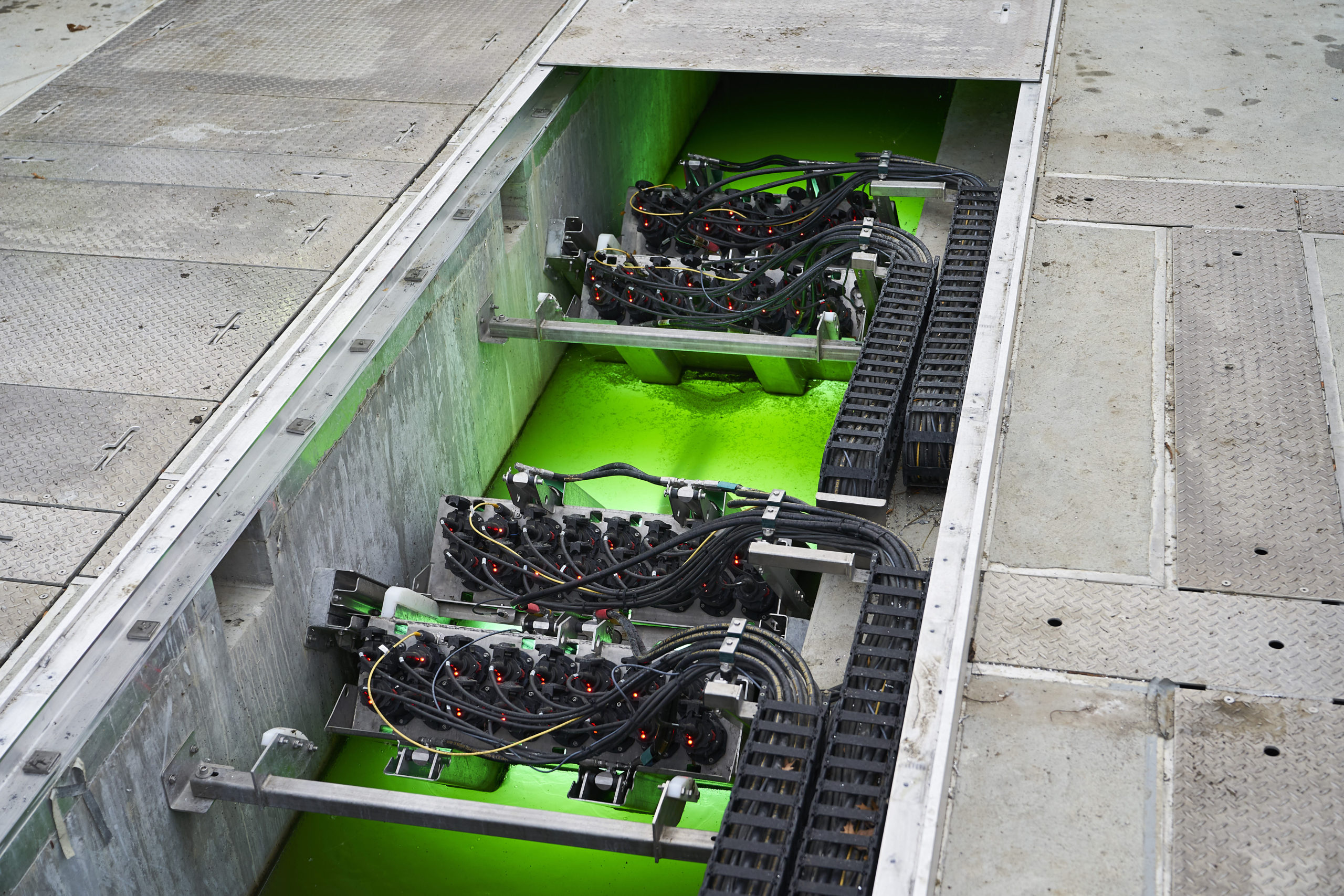

The TrojanUVSwiftECT installation at the Otter Lake Water Commission Treatment Plant.

To analyze these issues and develop a solution, the Otter Lake Water Commission conducted a series of studies. The analysis concluded that UV-oxidation was the most reliable option to obtain the required 1-log Cryptosporidium inactivation, while simultaneously delivering T&O treatment.

The plant passed performance testing in August 2014 and has successfully treated a T&O event. As of September 2014, the plant is capable of treating 1.7-log of MIB (2-methylisoborneol) and algal toxins, including year round treatment (2-log Cryptosporidium inactivation.)

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...