Helping Mercy Ships Deliver Hope & Healing

Mercy Ships has been providing humanitarian aid around the world for nearly 40 years. This non-profit organization provides free healthcare to at-risk coastal communities by converting ocean liners into floating hospitals. Comprised of a skilled team of surgeons, doctors and nurses, Mercy Ships brings state-of-the-art technology and medical training to those in need.

In 2007 the organization’s flagship, Anastasis, was retired from service, leaving Mercy Ships with a single vessel – the Africa Mercy, to aid regions in need.

Adding another ship to the fleet after Anastasis’ decommissioning had always been the plan. The newly acquired vessel will more than double the ability for Mercy Ships to administer its humanitarian efforts around the globe, and with a total of 6 operating rooms on board, having a clean, reliable surgical water system was crucial.

A Collaborative Approach

Thanks to a well-established history within the medical device and biomedical industries, Smith Engineering – a distribution partner of Aquafine, was referred to Mercy Ships as a potential equipment supplier. Smith Engineering was subsequently awarded the contract to provide the on-board surgical water treatment system without it going to bid, highlighting their reputation as an effective and dependable organization.

Smith Engineering also took the initiative to begin a company-wide fundraising campaign for Mercy Ships and has so far reached nearly $43,000 in donations. As a gesture of goodwill, Trojan Technologies also made a donation to offer further support for this great cause.

Accommodating Care

Everything one thinks of as being standard in a typical hospital, can be found on a Mercy Ship. And, like any hospital, infection control is of the highest concern. As such, it is imperative that the vessel’s water is fit not only for drinking, but also when being used during surgery.

With limited space for installation Smith Engineering developed an extremely modular system, outfitted with “soft” connections that would normally be hard piped, thereby allowing it to be disassembled and reassembled easily.

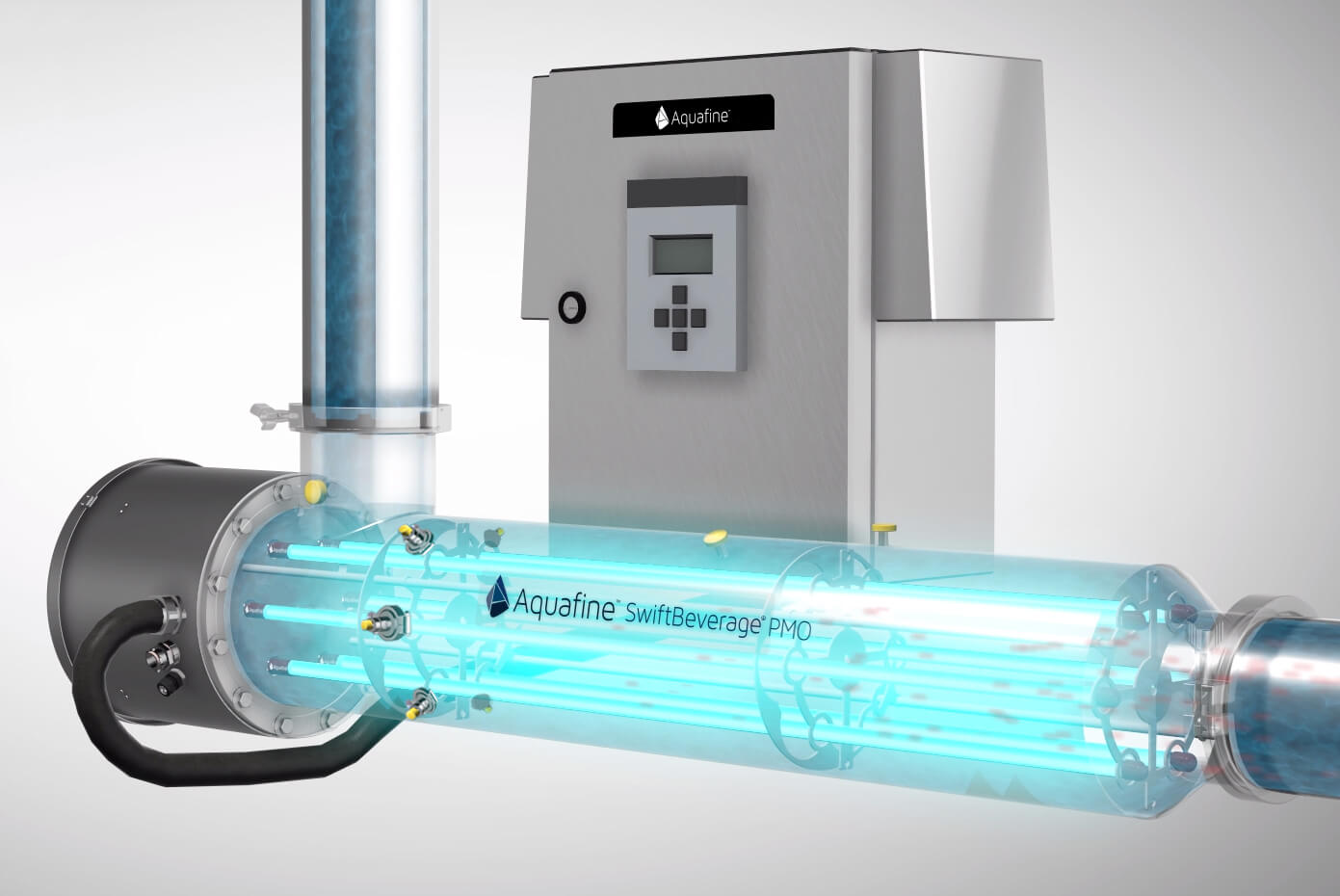

To further meet the customer’s needs, significant redundancy was built into the system, enabling it to function for long periods of time at sea without additional maintenance. The Aquafine UV system was the ideal complement for the application because of its user-friendly design and compact size.

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...