OptiVenn: Redefining Flexibility, Reliability & Robustness For Industrial UV Water Treatment

The OptiVenn Series is a suite of flexible UV systems, designed to meet the stringent requirements of pharmaceutical, food & beverage, microelectronics and other industrial markets.

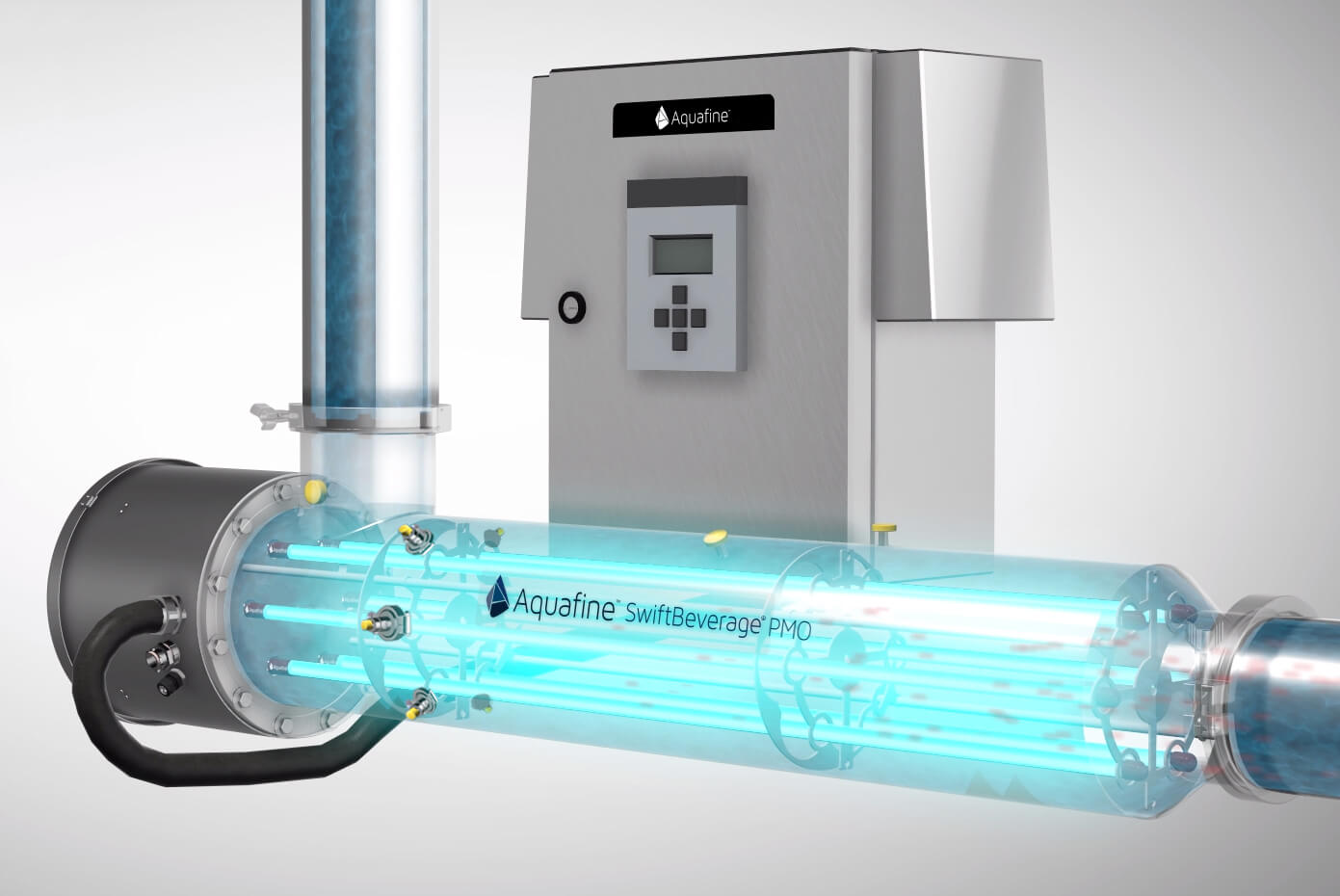

In order to help avoid costly production downtime, the OptiVenn was designed to be a reliable and robust system that incorporates the best features from our Aquafine product lines. The system also utilizes multiple lamps in the chamber, to allow the plant to continue running until scheduled maintenance by a certified Aquafine service provider.

Key Benefits of the OptiVenn System

Compact Footprint

- An optimized chamber design and multiple lamp arrays enable cost-effective installation in extremely compact spaces.

Flexible Chamber Design

- The configurable treatment chamber makes it easy to fit the UV System into small spaces and tight pipe networks. The cylinder can be rotated to allow inlet and outlet connections at 4 different angles.

Improved Lamp Technology

- Low-pressure high-output lamp (LPHO) technology provides increased process performance and extended lamp life.

Product Specifications

Both the treatment chamber and control panel are extremely compact, yet offer flexibility of installation to accommodate into different skid designs or as a stand-alone UV System.

Constructed of 316L SS, the treatment chamber is available in two finish options. The control panel is constructed of 304 SS and is equipped with a Universal Controller which provides control, monitoring and operational information in a single convenient location.

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...