TrojanUVSigna To Be Installed At Ashbridges Bay Wastewater Treatment Plant

After the completion of an extensive pre-selection and evaluation process, Trojan Technologies has been selected as the UV supplier for the treatment conversion and upgrade project at the Ashbridges Bay Wastewater Treatment Plant in Toronto, Ontario. It is the largest secondary treatment plant in Canada, with a rated flow capacity of 818 million liters (216 million gallons) per day and peak flow of 2,000 million liters (528 million gallons) per day.

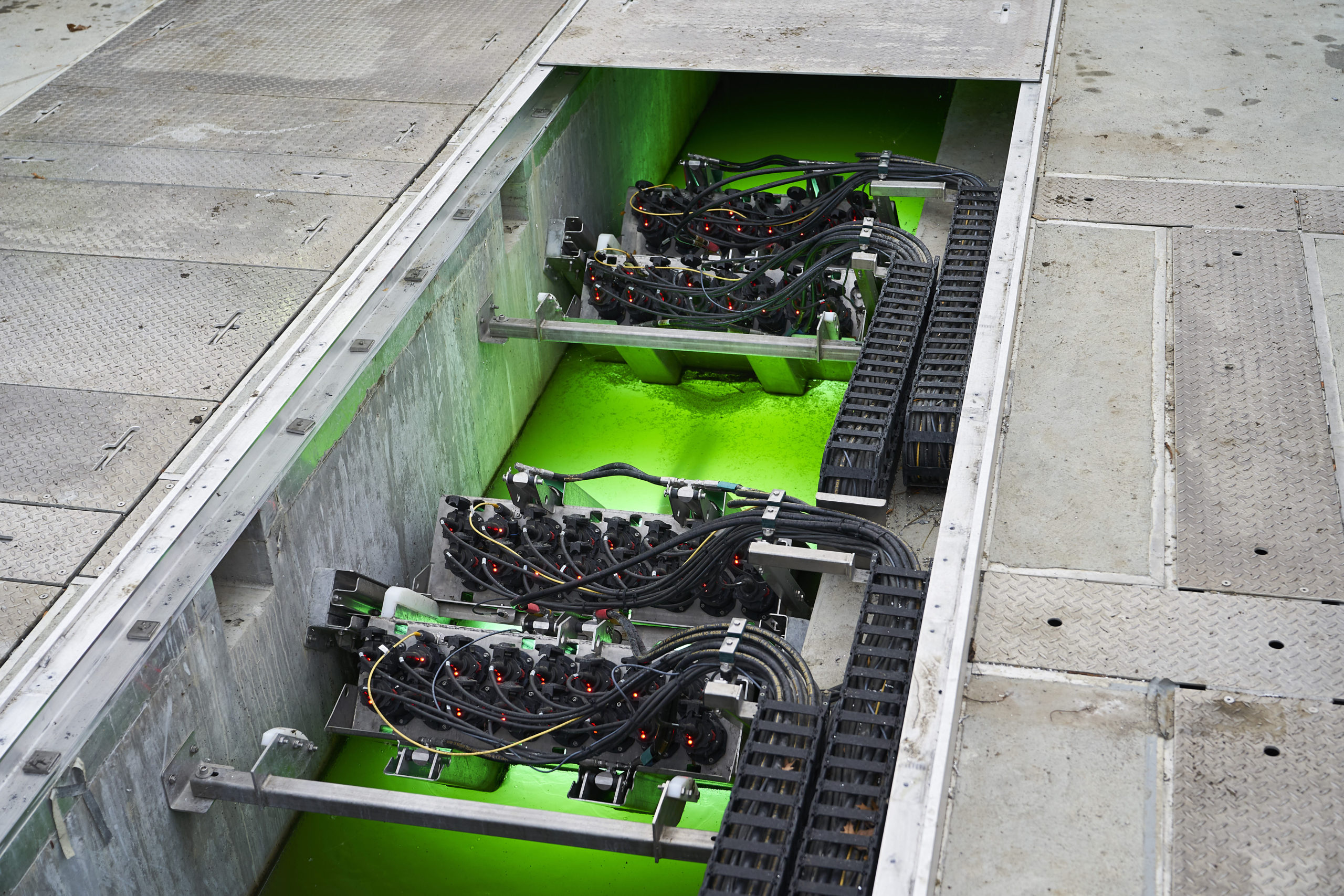

UV will become the plant’s main method of treatment (replacing chlorine) and will provide broad-spectrum inactivation of a wide range of microorganisms. The design will consist of 12 channels, each containing two TrojanUVSigna® banks of UV lamps. It is slated to be the largest TrojanUVSigna installation to date.

“We pride ourselves on helping municipalities build and provide water confidence, and are looking forward to working on this exciting project,” says Marv DeVries, president, Trojan Technologies. “At Trojan, we are continuously engineering and innovating for our customers, and our TrojanUVSigna is a prime example. It provides municipalities and treatment plant superintendents and operators with an treatment alternative that is compact, energy efficient, and easy to maintain.”

Project design, equipment manufacturing and UV building construction will be completed in late 2019.

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...