Supplying UV Equipment for Indirect Potable Reuse in France

Vendée Eau is securing a future supply of drinking water with the Jourdain programme, a demonstration facility that will purify treated wastewater to supplement the Jaunay Reservoir

Meeting the demand for clean water has never been more challenging. Communities around the world are facing a growing water stress – an insufficient supply, in terms of water quality or water quantity – and often both. Climate change, growing populations, aging infrastructure, and natural and man-made contaminants are contributing factors making it challenging for municipalities to meet the increasing demands for clean water. Many are turning to water reuse as their solution for securing a local, drought-proof water supply that also protects withdrawals on natural resources.

Regions that are most affected by droughts and water shortages have adopted wastewater reuse practices broadly. For example, nearly 90% of Israel’s and 15% of Spain’s wastewater is reused. Due to strict regulations, the practice is underdeveloped in France, but the public drinking water utility Vendée Eau aims to change that.

In Vendée, 9 out of 10 litres of drinking water comes from surface water that is particularly sensitive to the effects of climate change. In addition to actions promoting water conservation, Vendée Eau is preparing for the risk of a future water shortage.

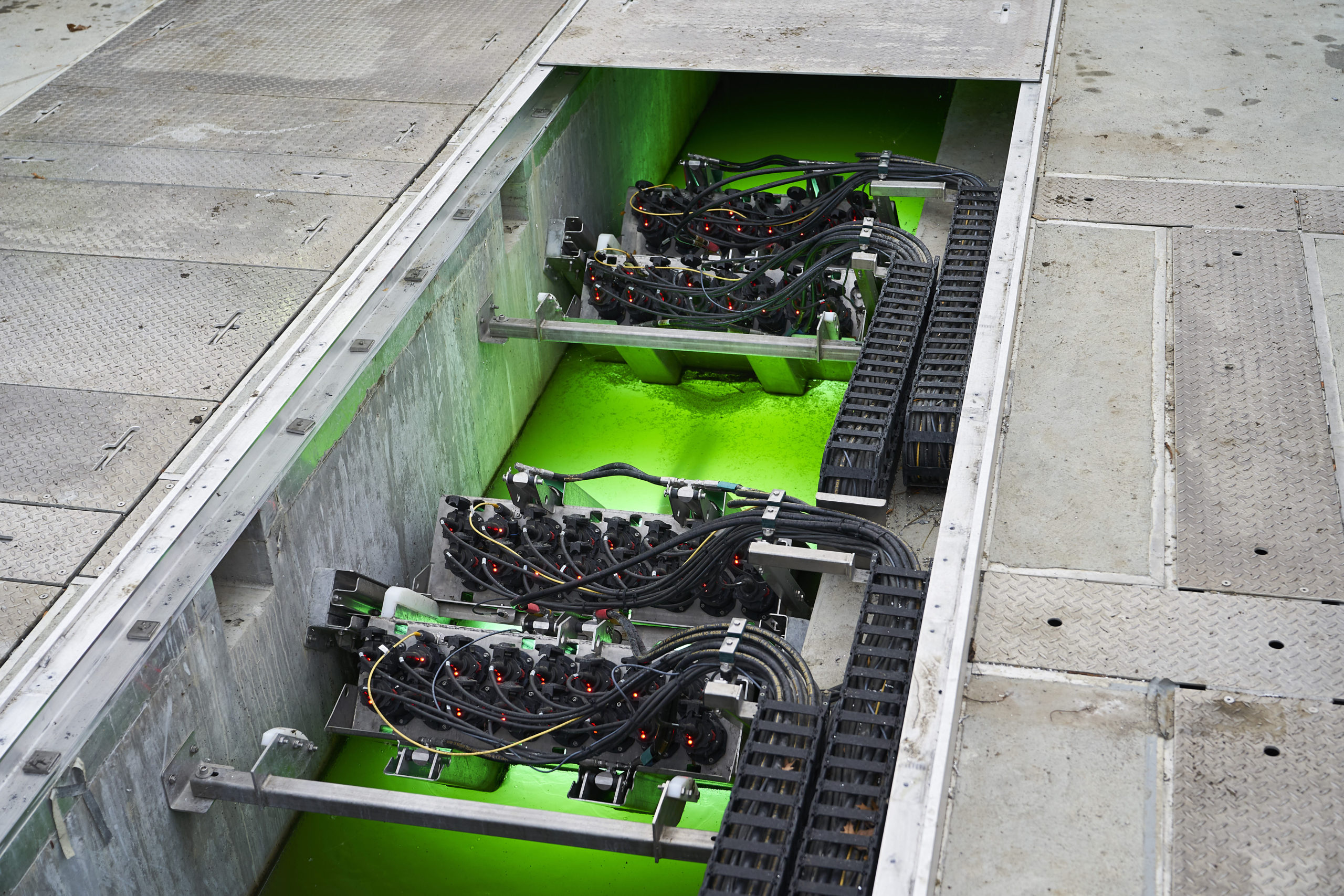

Construction of the Jourdain Programme Treatment Facility

Vendée Eau is securing a future supply of drinking water thanks to the Jourdain programme, a demonstration facility that will purify treated wastewater to supplement the Jaunay Reservoir. For this programme, Vendée Eau has entrusted Veolia with the design and construction of the tertiary treatment unit.

The start of construction of this facility was celebrated on July 6th, 2022, with an event hosted by Vendée Eau and Veolia in Les Sables-d’Olonne, France. Our Maryléne Bellier-Giovannetti (Regional Sales Manager) and Eduardo Gracia (Municipal Business Development) were honored to be there participating on behalf of Trojan as the UV equipment supplier for this project.

The July 6th event held in Les Sables-d’Olonne celebrated the start of construction of the Jourdain programme.

Construction of the treatment unit will be complete by the end of 2023 and will be complemented by the installation of a transfer pipeline and vegetalized buffer zone, after which environmental, health and social impacts will be assessed from 2024-2026. By the year 2027, the Jourdain programme will be evaluated for the potential to expand treatment capacity from 150 m3/h to 600 m3/h (1 to 4 MGD).

The future Jourdain programme treatment facility (Image credit: Vendée Eau)

The Wastewater’s Journey to Jaunay Reservoir

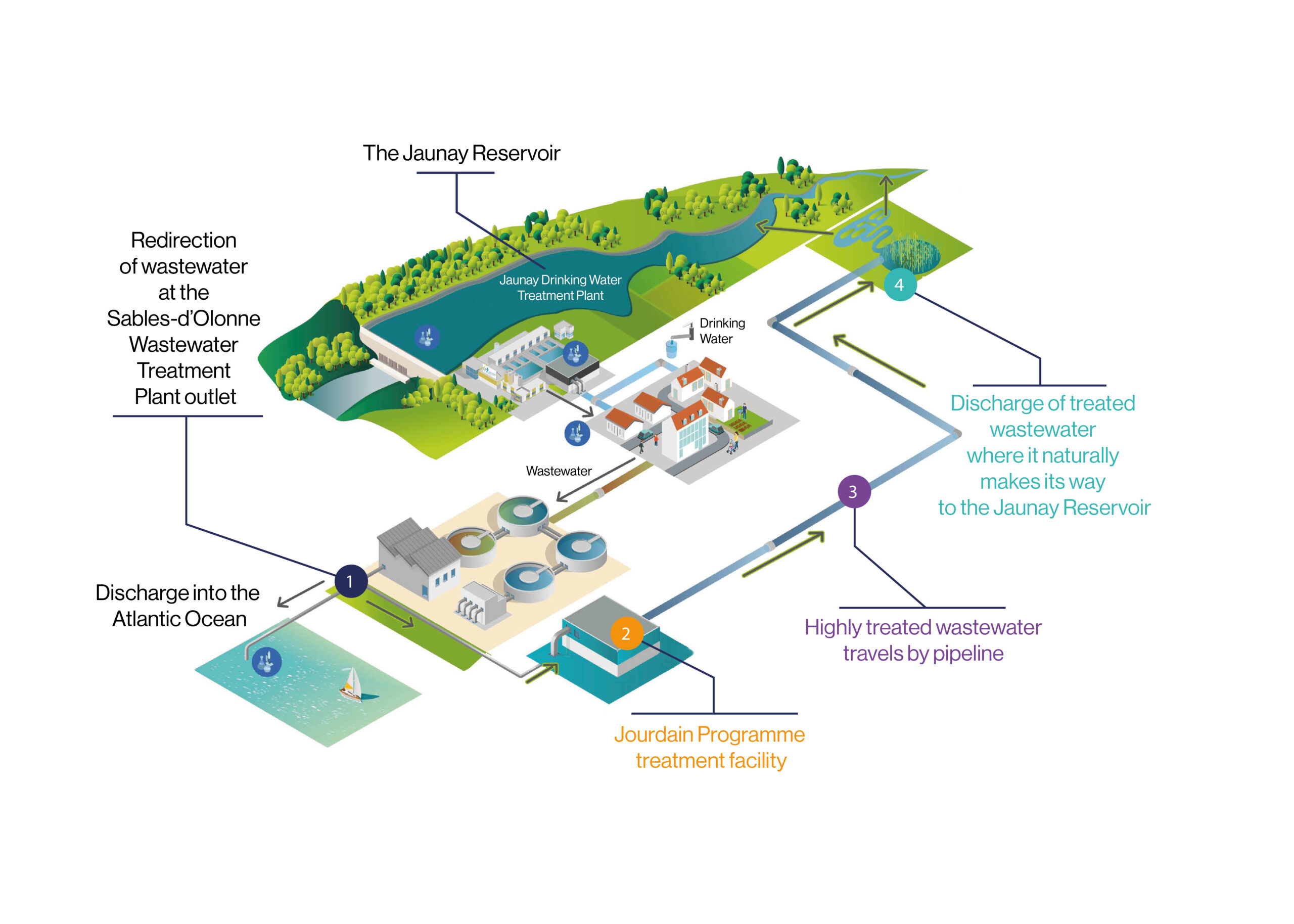

Indirect potable reuse is the process of treating wastewater for the augmentation of drinking water supplies. Treated wastewater is sent for further treatment with advanced processes that allow it to be released back into the environment where it will naturally make its way to the source water for drinking water treatment plants.

In Vendée, treated wastewater from the Sables-d’Olonne Wastewater Treatment Plant that was destined to be released into the Atlantic Ocean will instead be sent to the Jourdain programme demonstration facility. There, the water will go through a treatment process to eliminate salinity, microbiological compounds and micropollutants such as pesticides, pharmaceuticals and industrial compounds. The highly treated water will then travel over 27 km via a pipeline where it will be released into the environment. Naturally, the water will rejoin with the river and slowly make its way to the Jaunay Reservoir, which is source water for the Jaunay Drinking Water Treatment Plant.

An overview of how wastewater will be treated and travel to the Jaunay Reservoir (Image credit: Vendée Eau)

UV’s Role in the Treatment Process

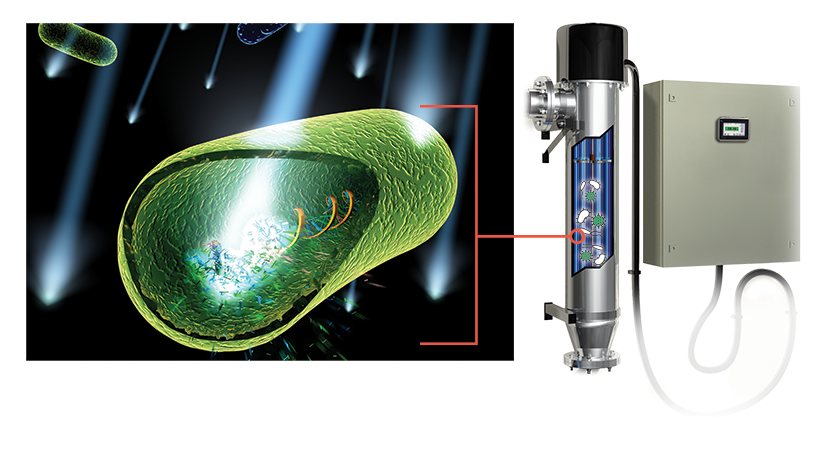

The treatment process to eliminate salinity, microbiological compounds and micropollutants begins with ultrafiltration and also Pall Water microfiltration, followed by Veolia’s reverse osmosis and desalination Barrel technology. A TrojanUV system then treats the water which is followed by chlorine and a rebalancing step. Hach’s products ensure water quality throughout the treatment process with reliable and instant measurements of phosphate, ammonia, UV absorbance, pH, Redox, suspended solids and turbidity.

The treatment processes with the Jourdain Programme treatment facility

UV is a crucial part of the process, providing treatment of microorganisms E.coli, Enterococcus, F-specific RNA phages, spores and chlorine-resistant Cryptosporidium and Giardia. It is a simple, cost-effective technology that adds nothing to the water but UV light and does not create by-products.

In other applications UV can also, through an optimized process called UV Advanced Oxidation, break down chemical contaminants such as pharmaceuticals.

When microorganisms are exposed to wavelengths of UV light, their genetic material is damaged, and they are instantaneously rendered incapable of reproducing

Further Reading/Information

To learn more about this exciting project, or to read more about UV for water reuse please use the links below:

• Video Overview of the Jourdain Treatment Process (English)

• Video Overview of the Jourdain Treatment Process (French)

• Veolia

• Vendée Eau

• UV for Water Reuse

Featured Posts

La primera planta piloto de reutilización de agua potable en Europa utiliza Trojan UV AOP

Trojan se enorgullece de formar parte del proyecto de purificación de agua AIGUANEIX del Consorci d'Aigües Costa Brava Girona Trojan Technologies se complace en compartir que formamos parte del proyecto piloto de reutilización de agua AIGUANEIX de la Diputació de...

First Potable Reuse Demo Plant in Europe uses Trojan UV AOP

Trojan is proudly part of the Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water purification project Trojan Technologies is excited to share that we’re part of Diputació de Girona and Consorci d'Aigües Costa Brava Girona’s AIGUANEIX water reuse pilot project at...

Trojan Technologies Opens First U.S. Distribution Facility in Grand Rapids, Michigan

On March 3, 2025, Trojan Technologies celebrated the grand opening of its first U.S. distribution center in Grand Rapids, Michigan. This strategic expansion underscores the company's dedication to enhancing customer experience and optimizing the delivery of its...